Plastics

We invented something even fungus would not eat and our greatest challenge today is that it does not decompose!

Since the dawn of mankind, we have made things. Things that would make it easier for us to undertake tasks, things that would be useful to us and things that serve aesthetic purposes. Most of these thing for most of history were made out of natural materials.

The most hardy of all the materials that humans used throughout history were rocks. We know this because it is standardly found at every archaeological dig. It is not like no other materials were used, it is probably the only thing that survived the test of time.

Even human history is divided into ages based on the materials we were using - Stone Age (Mesolithic and Neolithic), Bronze Age (Copper and Bronze), and Iron Age. The Iron Age finally spills into the Steel Age that we are supposed to be in.

But really, the last 30 years can easily be classified as the Plastic Age.

Even in the 19th century, we were still using wood and metals to make most things. The problem was that all of these have a tendency to decay over time.

What is decay?

Well, it is described as rot due to the action of fungi or bacteria. Decay put simply is your stuff turning into food for microorganisms.

Apart from decay, wood does not weather too well. It swells when exposed to moisture, and shrivels when dry. On the other hand, all metals are consumed by Oxygen eventually. They react with atmospheric Oxygen and rust.

The Statue of Liberty, an incredibly well-known monument was Reddish Brown when it arrived in the US from France. It turned green due to oxidation which is the decay of the metal. It is a matter of time before it gets fully consumed.

Fabric tends to have an even lower lifespan.

People wanted things that were much more durable. There was this constant search to take decay out of the life of every item.

The search for durability gave us plastics. The first plastic to be used was Bakelite which was invented in 1907. If you go to a really old house you might still find switches made out of Bakelite. It is a very easily moulded plastic but once set it is resistant to heat, corrosive solvents, and electricity. Its shortcoming is that is not flexible once set.

The search for greater properties such as malleability, flexibility and absence of brittleness, gave us a steady stream of new plastics throughout the 20th century.

We got Cellophane, PolyVinyl Chloride, Neoprene, Polystyrene, Polyethylene, Nylon, Polytetrafluoroethylene, Polyethylene Terephthalate (PET), Polyester, Polypropylene, Polycarbonate and Kevlar.

Their only greatest property - they do not decay.

Alright. So they had created a material that would not decay, rust, corrode or wear over time. So we had a solution that could put us out of the misery of having to make the same things over and over. We could finally give everyone enough and call it a day.

Welcome Capitalism.

Capitalism dictates that we should sell stuff even if the other person has no need for it. It is the foundation of capitalism.

So a plan was needed!

Sell it so cheap that it is disposable. Also, tell them it is recyclable!

So here is the deal with recycling. The only plastics that can be recycled are plastics that are see-through and do not include any colour in them. Yes, coloured plastics can be shredded into fibres and turned into shoes or clothes but that is a very cumbersome process and is not being done at scale currently.

So less than 10% of the plastic waste across the world can be recycled. Even in that 10% let us consider a bottle of Coke.

Now a bottle of coke has three types of plastic. The bottle itself, the cap and the wraparound branding. Being able to recycle the bottle implies being able to separate all three of these efficiently first. When someone in London throws a bottle of coke in the recycle bin, they are just going to put it on a long polluting journey to Turkey or some Eastern European nation where it will be dumped so that the English countryside can remain idyllic.

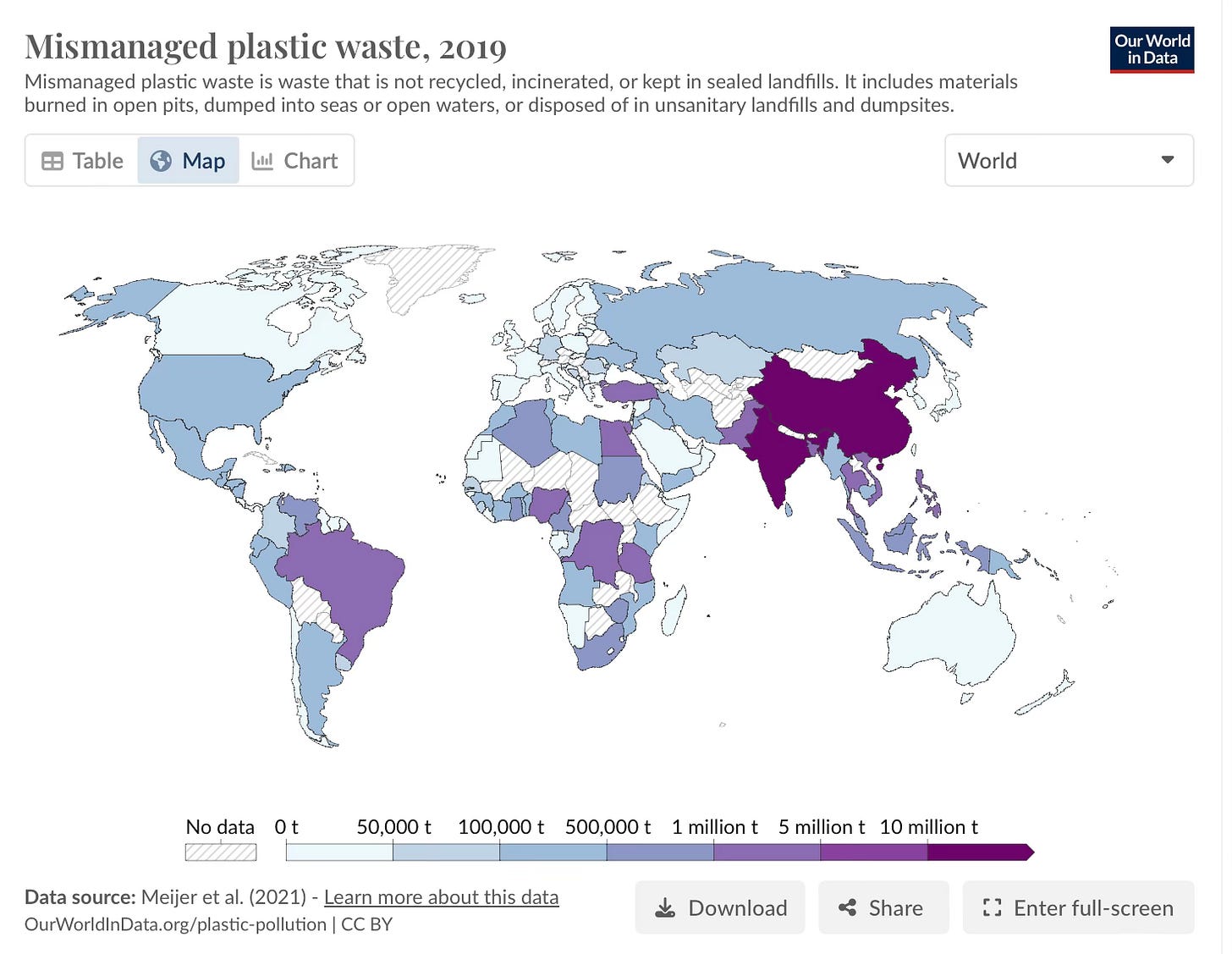

Source: Our World in Data

In India, China, and several developing nations there is no process in place to recycle even that 10%. Given the huge populations, the volumes generated from both nations are insane.

Source: Our World in Data

Just to recap

1 - We created a material which will not decay

2 - We convinced people they should buy a lot of it and throw it into the garbage so that the companies that make this garbage can make a lot of money

And now…

Plastic is everywhere. If you eat seafood, you are certainly eating microplastics. Our waters are full of plastics and microplastics. All of our waterways are choked with plastics. Fish spawns have reduced drastically because they live in this plastic. The lands are filling up with plastics and it is getting to a point where it is starting to affect agriculture.

So what are we doing?

We are working to try and convince fungus to eat this shit that was expressly made not to be.

A Japanese professor identified a bacteria in the city of Sakai that seemed to be consuming PET.

Ideonella sakaiensis is a bacterium from the genus Ideonella and family Comamonadaceae capable of breaking down and consuming the plastic polyethylene terephthalate (PET) using it as both as carbon and energy source. The bacterium was originally isolated from a sediment sample taken outside of a plastic bottle recycling facility in Sakai City, Japan

Source: Wikipedia

There was an immediate rush to see if it could be put to work to overcome the mountains of garbage that we have produced and at the same time if it could be genetically modified to consume other plastics.

While commercialisation has been slow, France is one country that has committed to making this mainstream. The first company commercialising this technology is a French company called Carbios.

Of course, Capitalism implies you cannot just let the being do what it must. You have to patent what a being does! Like that, we arrive at “Proprietary Enzymes”.

Our research team is working to develop enzymes naturally present in our environment in order to optimize their polymer degradation activity and their heat resistance. The activity and thermostability of enzymes are essential assets for their efficient and competitive implementation in our industrial processes.

This work is mainly carried out in collaboration with the TBI laboratory (Toulouse Biotechnology Institute) and notably via the cooperative laboratory, PoPLaB (Plastic Polymers and Biotechnologies), co-founded with INSA. In April 2020, Nature, the most prestigious scientific journal in the world, praised the innovative nature of this enzymatic engineering work which paves the way for a virtuous management of the life cycle of plastic (and textile) materials.

To date, we have developed proprietary enzymes with the ability to break down certain polyesters, in particular PET (polyethylene terephthalate), which is very common in bottles and textiles, and PLA (polylactic acid), a biobased polymer.

Our optimized enzymes are now used in two innovative processes: enzymatic recycling and the production of biodegradable plastics.

Source: Carbios

So in summation, nature supplied us with plenty of materials that would naturally degrade, instead we dug up dinosaur corpses and figured out how to make a material that can serve as food to nothing. Then we convinced our species to buy as much of it as possible. We found so much success that it is now indistinguishable from air, water and land.

Finally, we found some poor little bacteria that would eat even that and now we are torturing its genetics in the lab so that we can make some money out of that as well!